capabilities

WE can modify or manufacture specialty parts

If you're looking to bring your prints or descriptions to life, look no further!

Our experienced team will turn your visions into reality.

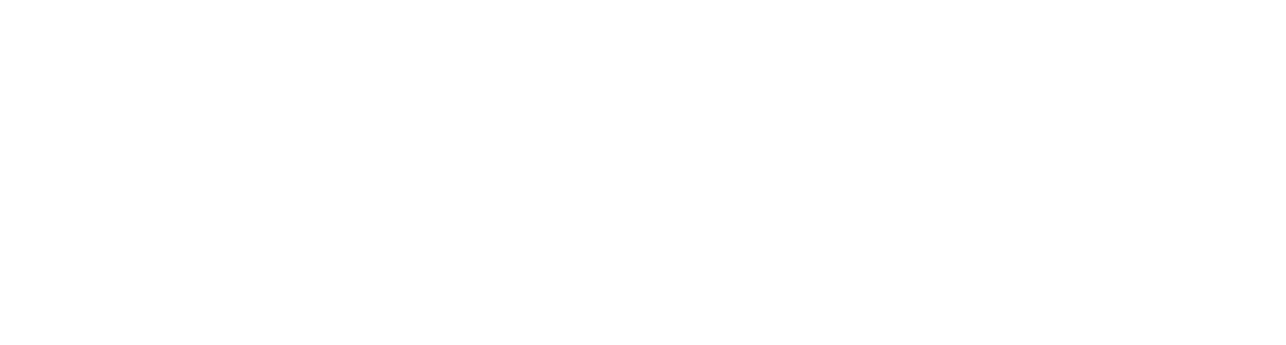

(3) CNC Milling Centers

Discover precision machining excellence through our advanced CNC milling centers, offering versatile capabilities and cutting-edge technology that unveil the prowess of our high-tech CNC milling expertise.

100 Ton Press Brake

Master precision bending with our 100-ton press brake, seamlessly merging cutting-edge technology and robust capabilities to redefine standards in precision metalworking.

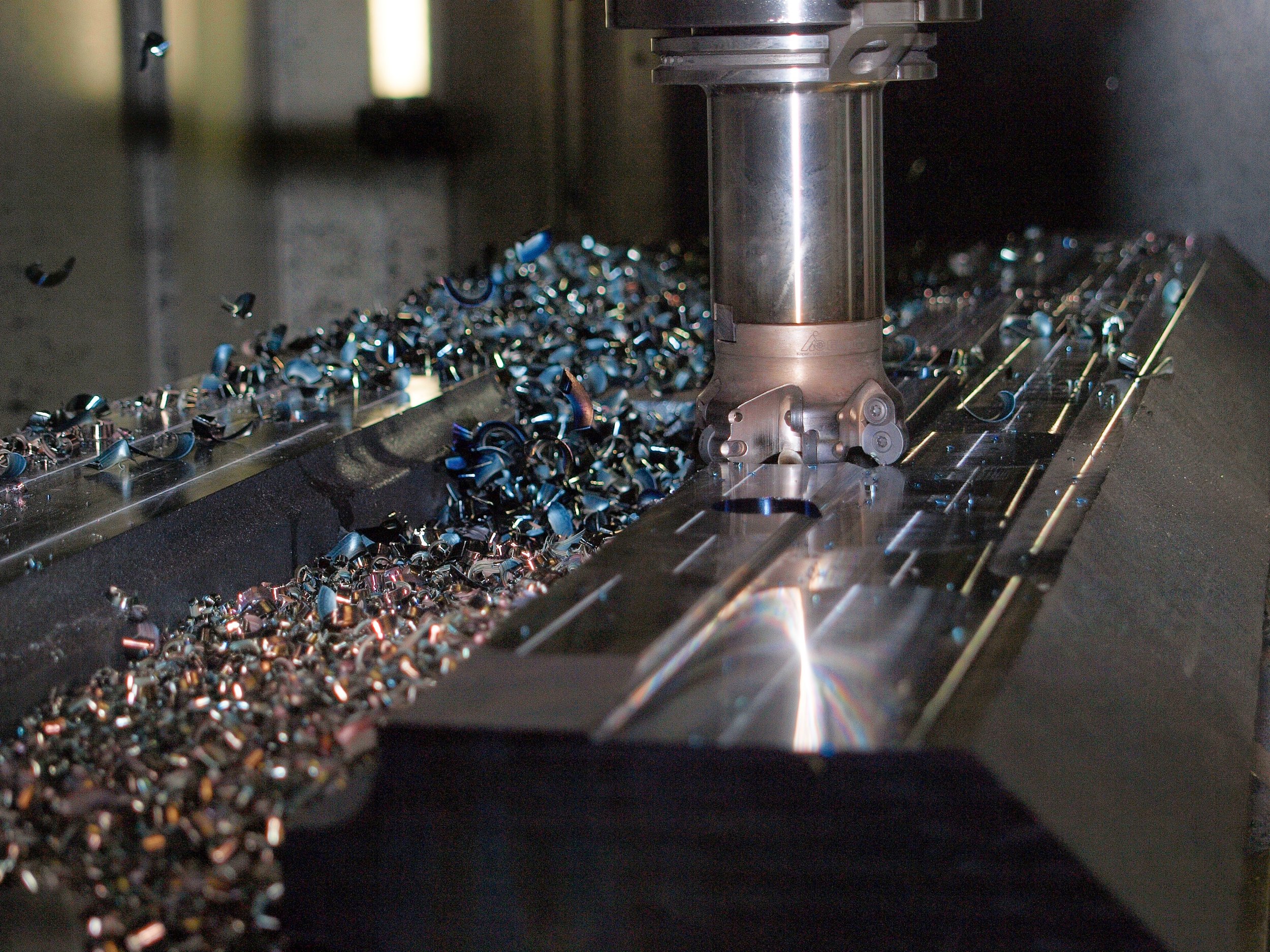

(6) CNC Turning Centers

Embark on a precision journey with our CNC turning centers, uniting cutting-edge technology and versatile capabilities to set a new standard in machining excellence and showcasing the exceptional proficiency of our advanced CNC turning expertise.

Centerless Grinding

Achieve precision perfection with our centerless grinding, uniting state-of-the-art technology and meticulous capabilities to redefine standards in precision metal finishing.

Multiple Waterjets

Experience precision manufacturing with our multiple waterjets, seamlessly combining cutting-edge technology and versatile capabilities to redefine standards and showcase exceptional proficiency in advanced waterjet expertise.

Manual Lathes

Craft with precision using our manual lathes, where traditional craftsmanship meets modern engineering to redefine standards in manual machining capabilities.

WE also offer:

Autofeed Production Saw (for Cut-to-Length Studs)

Stud Master to Chamfer & Grade Stamp Cut-to-Length Studs

Pneumatic CNC Dot Peen Engraving Machine

reverse engineering services

Need a repair part for a piece of equipment built in 1946? No drawings and the manufacturer out of business?

We can reverse engineer for you!

Identify alloy

Test Hardness

Create drawing

Manufacture

Our 4 Step Process guarantees you the parts you need. First, we identify the alloy with a Niton XRF Material Analyzer. Next, we test the hardness. Then, we generate a drawing for customer approval. And lastly, we manufacture per customer specifications after review of material, establishment of tolerances, surface finish requirements, and any other requirements to ensure acceptability for form fit and function.