INDUSTRIAL Pins

Pin fastener products are a type of specialty fastener that come in two general categories: semi-permanent and quick-release. Semi-permanent pins call for extra pressure or a tool to install and remove. Quick-release pins are self-contained and are frequently used in machine applications that require rapid manufacturing. They lock into place as a result of a special spring-loaded mechanism, which enables them to be installed and removed quickly. For industrial applications, machine pin fasteners are typically used, such as ground dowel pins, taper pins, standard cotter pins, and clevis pins.

Spring Pins

Cotter Pins

Clevis Pins

Clinch Pins

Grooved Pins

Threaded Taper Pins

Need something custom? Contact Us

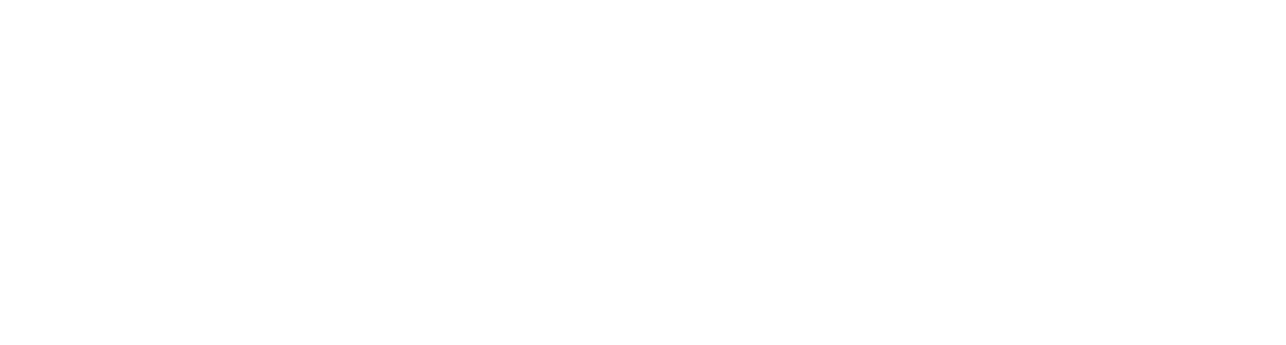

Spring Pins

Spring pins, also known as roll pins or split pins, are cylindrical fasteners with a spring-like design. These pins are used to secure two or more components together by expanding within a hole or groove. Spring pins offer flexibility and shock absorption, making them suitable for applications requiring vibration resistance and consistent alignment. Discover how spring pins provide reliable fastening in automotive, machinery, and industrial equipment assemblies.

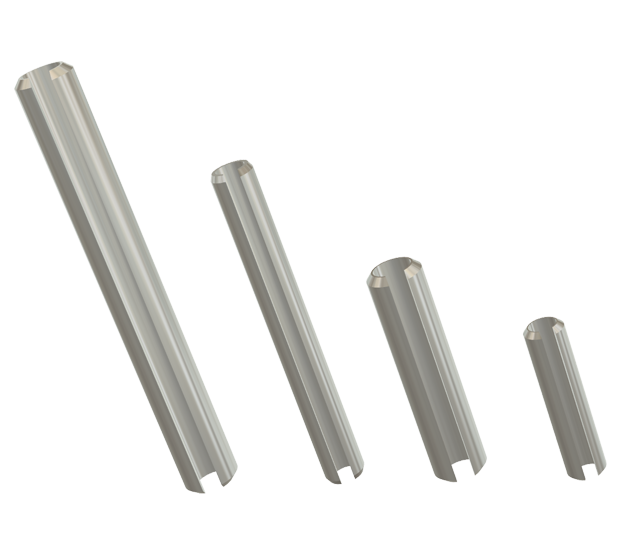

Cotter Pins

Cotter pins, also called split pins or cotter keys, are U-shaped metal fasteners with prongs that are bent to secure bolts, nuts, or other components. These pins prevent loosening due to vibration and provide a simple yet effective locking mechanism. Learn about the versatility and reliability of cotter pins in securing critical connections in automotive, construction, and marine applications.

Standard Pin Materials:

Steel

300 Series Stainless

316 Stainless

416 Stainless

NiCu 400 (Monel)

Special Pin Materials:

Inconel 625

Silicon Bronze

Alloy 20 ( Carpenter 20)

904L

Hastelloy C276

Hastelloy B

Hastelloy C22

2205 Duplex

Ferralium 255

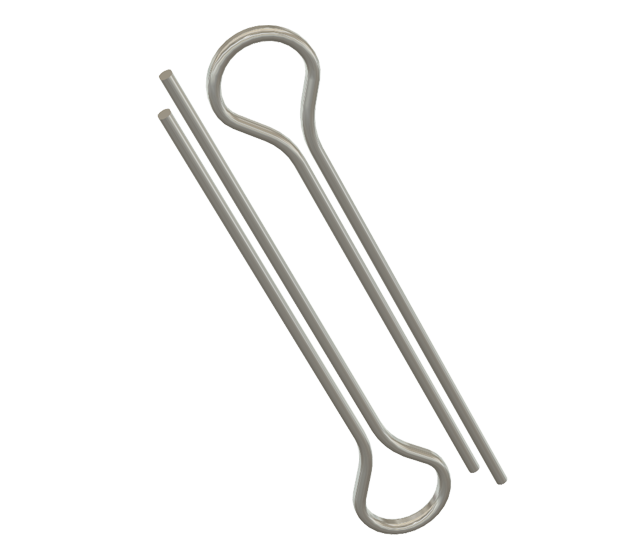

Clevis Pins

Clevis pins, also known as hitch pins or quick-release pins, feature a cylindrical body with a drilled hole for a cotter pin or retaining ring. These pins are used to connect linkage components such as rods, levers, or clevises in mechanical assemblies. Clevis pins allow for easy installation and removal, making them ideal for applications requiring frequent adjustments or maintenance.

Clinch Pins

Clinch pins, also referred to as linch pins or R-clips, are simple and effective fasteners used for quick and temporary assembly. These pins feature a looped or bent shape that snaps into a pre-drilled hole, providing a secure and removable connection. Explore how clinch pins offer convenient fastening solutions in agriculture, landscaping, and machinery maintenance.

Grooved Pins

Grooved pins, also called parallel pins or spring pins, are solid cylindrical fasteners with external longitudinal grooves. These pins are designed to be press-fit into a drilled hole, providing strong and permanent fastening. Grooved pins offer precise alignment and high shear strength, making them suitable for heavy-duty applications in automotive, aerospace, and manufacturing industries.

Threaded Taper Dowel Pins

Threaded taper dowel pins, also known as taper pins, are cylindrical pins with a taper along their length and external threading. These pins are used to align and secure components in machinery and tooling applications. Threaded taper dowel pins provide strong, vibration-resistant connections and can be easily installed and removed using standard tools. Learn about the benefits of threaded taper dowel pins for precise and reliable assembly in various industrial settings.

MATERIALS

We are proud to be a distributor and manufacturer of this product in a wide range of metal alloys.

Need something custom? Contact Us

Steel (Grade 2, Grade 5, Grade 8)

300 Series Stainless (18-8, 303, 304, 310, 316, 321, 347)

400 Series Stainless (410, 416, 420, 422, etc.)

Duplex Stainless (2101, 2205, 2507, 255, Zeron 100®)

High Strength Stainless and Nickel Alloys (A286, Hastelloy® C276, Inconel® 625, Inconel® 718, K-Monel®, Monel® 400, etc.)

High Temperature Allows (Haynes® 230, Waspaloy®, MP159®, etc.)

ASTM Specifications (ASTM A193, ASTM A320, ASTM A194, ASTM A453, ASTM A540, ASTM A1082, etc.)